5 Ways Mobile Devices are Transforming Warehouse Management

The warehouse management technology market continues to grow at a rapid pace. Industry growth in the warehouse app market is being fueled by the increased need to meet rapid fulfillment demands at lower cost.

At the same time, advances in mobile warehouse software are making these technologies more accessible, driving efficiency gains for inventory control.

Its rapid rise highlights a changing dynamic—modern warehouses face new opportunities to leverage inventory apps to maximize visibility across a wide range of operations. Heightened transparency allows supply chains to coordinate activities with tight precision and align business operations between departments and teams.

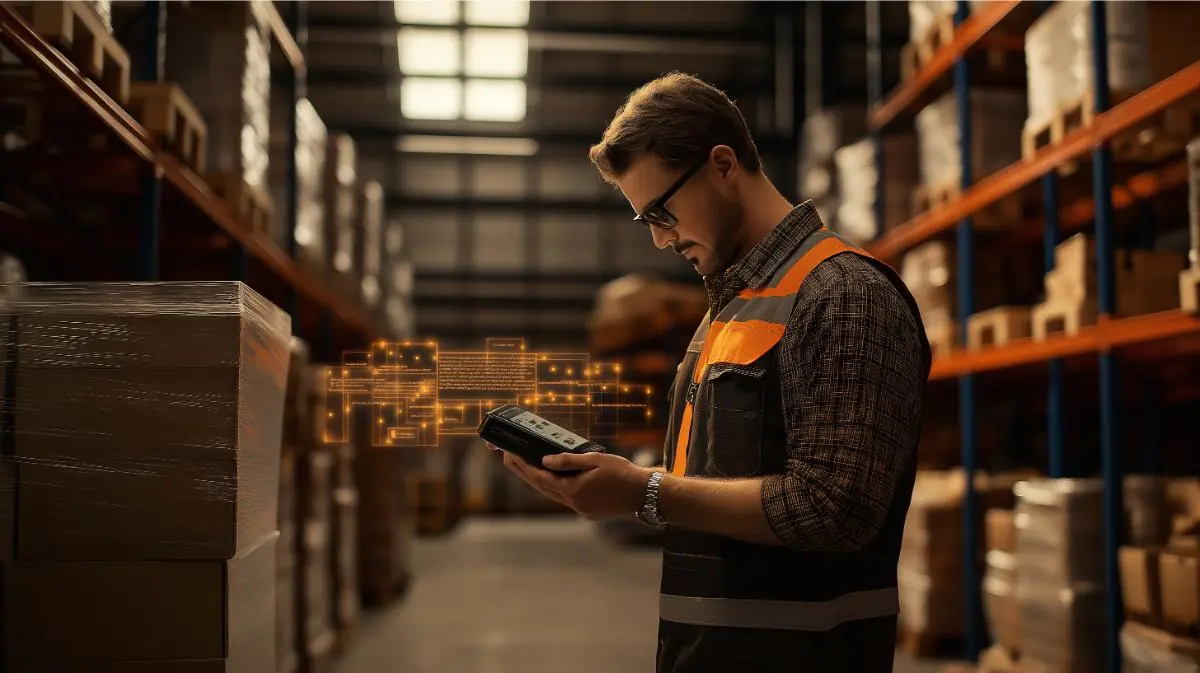

But these goals are only achievable if frontline workers have the mobile devices, barcode apps, and data collection tools needed to get the job done.

Mobile hardware solutions are transforming warehouse logistics, driving efficiency throughout the supply chain. Here are five of the most prominent gains offered by mobile devices:

1. Geographic Flexibility

Imagine your organization has long operated a centralized warehouse that has been able to handle fulfillment requests across your target markets. However, recent growth into new regions has left your teams struggling to keep up.

With today’s mobile inventory solutions, supply chains can more easily manage stock beyond central locations, so facilities can coordinate activities with relative ease.

For example, an organization that wants to improve product delivery can roll out a specialized warehouse for products in high demand closer to customers so they can send deliveries out faster. Live inventory visibility from a central ERP ensures materials are stored in the most strategic locations without getting lost.

Remote data collection and barcode scanning enable companies to establish teams devoted to specific supply chain, distribution, or fulfillment tasks in the most productive locations possible. This geographic flexibility can lay the groundwork for business innovation by eliminating problem-solving barriers.

RELATED: Ready to give your bottom line a boost? Mobilize your warehouse team »

2. Reduced Overhead for Remote Facilities

Many industrial organizations maintain locations in remote parts of the world where specialized operations take place. Geographic realities are a major issue in sectors heavily dependent on raw materials, natural goods, or unique market dynamics. There may be times when a warehouse with a skeleton crew operates so far away from the primary facilities that managing the remote warehouse presents a major operational burden.

Sending managers and specialists out to the remote facility isn’t practical, nor is neglecting the remote warehouse a viable option. Leveraging remote device management functionality in warehouse mobile apps offers a solution. This enables management to monitor warehouses from afar and even change parameters within automated systems to solve basic problems.

In addition, mobile platforms empower IT staff to troubleshoot devices and provide training for warehouse workers without traveling to the site—a huge efficiency gain.

Advanced offline data collection solutions further simplify enterprise oversight. If the system connection is lost at any point, offline mobility keeps inventory operations running until connectivity is restored.

In this way, geographical boundaries don’t have to hold your warehouse data collection back.

ALSO READ: Start creating value with warehouse automation software »

3. Adaptable Inventory Models

Lean manufacturing models are pushing organizations to eliminate waste in every way possible, including reducing the quantities of materials sitting on shelves unused. Having pending orders sit idle while workers spend up to 60% of their time walking between production lines and warehouse storage creates significant waste.

To compensate, some operations store small numbers of parts, supplies, and other materials near production. The problem with this strategy is that poor visibility into inventory levels limits monitoring of available stock at each facility.

This is where mobile inventory technology pays off.

Having a mobile barcode scanner in hand lets users log and locate inventory in a matter of seconds, feeding that information back into the ERP. Changes in stock levels, status, consumption, and origin are kept seamlessly up-to-date for facilities, regardless of inventory management model.

Whether or not your business is interested in this variety of lean operations, the reality is that greater visibility into inventories gives you an opportunity to establish parts storage and supply strategies that align with your specific operational demands.

4. Simplified Training

Warehouse technology can be incredibly useful in meeting specific operational needs. But heavyweight solutions like WMS software can also come with a heavy training burden.

More intuitive, cost-effective alternatives like mobile barcoding put a familiar user experience in the hands of workers that isn’t technologically overwhelming. Comfort with the interface and well-designed UX translates to 80% faster warehouse training and much higher user adoption.

5. Enhance Field Service Management

Field service management is often a blind spot for inventory management. Long-standing limitations in tracking vehicle locations, the inability to immediately process work orders and inventories in the field, and similar issues can make it difficult to pinpoint material movements.

However, field services have a huge impact on both internal and external stakeholders. Giving drivers mobile apps for field services lets them submit bills electronically during customer interactions, record inventory updates when they use assets stored in their trucks, capture signatures on-demand, and quickly update team members back in the warehouse.

Increased complexity across the supply chain, not to mention demand for greater speed and precision during the fulfillment process, is pushing organizations to enhance oversight across all operations. Field service software that extends core warehouse and ERP systems allow companies to gain greater visibility and productivity while offsite.

Using Mobile Technologies to Gain a Competitive Edge

Smartphones and tablets are transforming operations across plenty of industries, and the time has come for supply chains to catch up. The combination of visibility and speed offered by mobile barcoding apps is invaluable in a sector that depends on tight controls to remain profitable.

While pressure to ramp up efficiency without sacrificing quality continues to strain warehouse management and manufacturing, businesses that modernize operations with mobile warehouse technology are bound to succeed in the blistering pace of an increasingly digital world.

Transform Your Supply Chain

Overcome labor challenges, slash costs, and transform inventory control with next-gen mobile data collection. Talk to an RFgen expert today!