What is Warehouse License Plating?

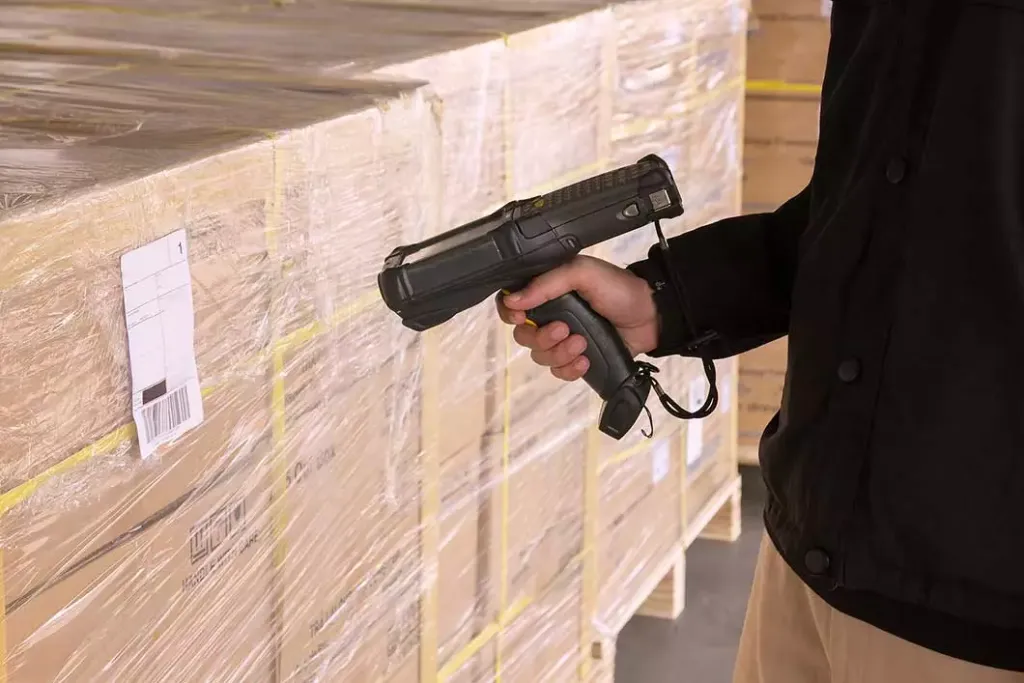

License plating is a method for grouping and managing inventory in the form of a container. You decide what constitutes a container—a pallet, product carton, truck or ocean freight box can all be a container. Each container is assigned a unique License Plate Number (LPN) and given a barcode label or RFID tag. With RFgen Inventory License Plating, you can manage logistics and track key information for a group of items with a single scan, simplifying traceability.

WHAT YOU GET

With RFgen License Plating, you can intelligently manage a group of items as a single unit. This can improve the efficiency of your warehouse operations and streamline the transfer of inventory within your supply chain as well as to customers, retailers, and partners.

A license plate can contain similar materials or mixed products. Once information is associated with the license plate, a dedicated barcode or RFID tag can be placed on the container, so that a single scan identifies and tracks every item within.

A license plate can be associated with information such as:

- Part numbers

- Item

- Quantity

- Revision

- Serial number

- Organization

- Date of manufacture

- Expiration date

- Lot number

- Location

- Inventory status

- Subinventory

While license plating and pallet labels are often associated with outbound shipments, they can be beneficial throughout the supply chain.

- Receive shipments faster – assign license plates to incoming parts and materials or upload vendor license plate information into your system ahead of time for single-scan receiving.

- Put away items in kits – create a license plate at the receiving docks to quickly kit for manufacturing.

- Flexible receiving – pack, unpack, consolidate, and split shipments in receiving by scanning and updating license plates.

Use license plates with work orders to stage multiple inputs:

- Create a license plate of raw material – essentially a parts list you need to complete a work order.

- Pick these items from the warehouse – deliver the entire license plate of parts to the shop floor and stage the materials around the workflow.

- Manage consumption – workers can scan the license plate, measure how much material is being issued for the process, and subtract the amount from inventory.

- View inventory balances by license plate, so you can proactively stage more materials.

Speed up picking in the warehouse with license plates:

- Identify the most popular items in your warehouse and ensure that the pick routes are short and timely.

- Use license plates to group products normally purchased together – instead of scanning individual products when an order for the group of products comes in, quickly scan one license plate.

- License plating supports nontraditional forms of picking, such as directed picking and wave picking.

- Confirm and track containers as they are loaded to ensure that all planned containers are accounted for, improving load accuracy and maximizing space. In transit, quick scans of license plates along the way help you keep customers informed of the status.

- Build and manage loads more easily – RFgen License Plating with load management functionality uses the information contained in multiple license plates to plan and manage routes, work within weight restrictions and create proper shipping documents. The load management functionality nests these license plates to create a single load that can be scanned as one overarching license plate.

- Print labels and shipping documents for bills of lading and Advanced Ship Notices (ASN).

- Labeling Compliance – More and more supply chain companies require that pallets and shipping containers be properly labeled. RFgen License Plating helps you comply with labeling compliance through on-demand barcode label generation and printing.

- Easily comply with EDI labeling requirements, such as Advance Ship Notices (ASN), UCC 128, or SSCC

- Food Traceability – Enable faster response times for audits and recalls by capturing critical information in bulk for lot number tracking and global batch traceability.

Cindy GarrettDirector of IT, Caito FoodsNow with RFgen every item number has a license plate attached to it. We can bring up the item number in the date range and create a report within minutes to show auditors the actual purchase order that it came in on.