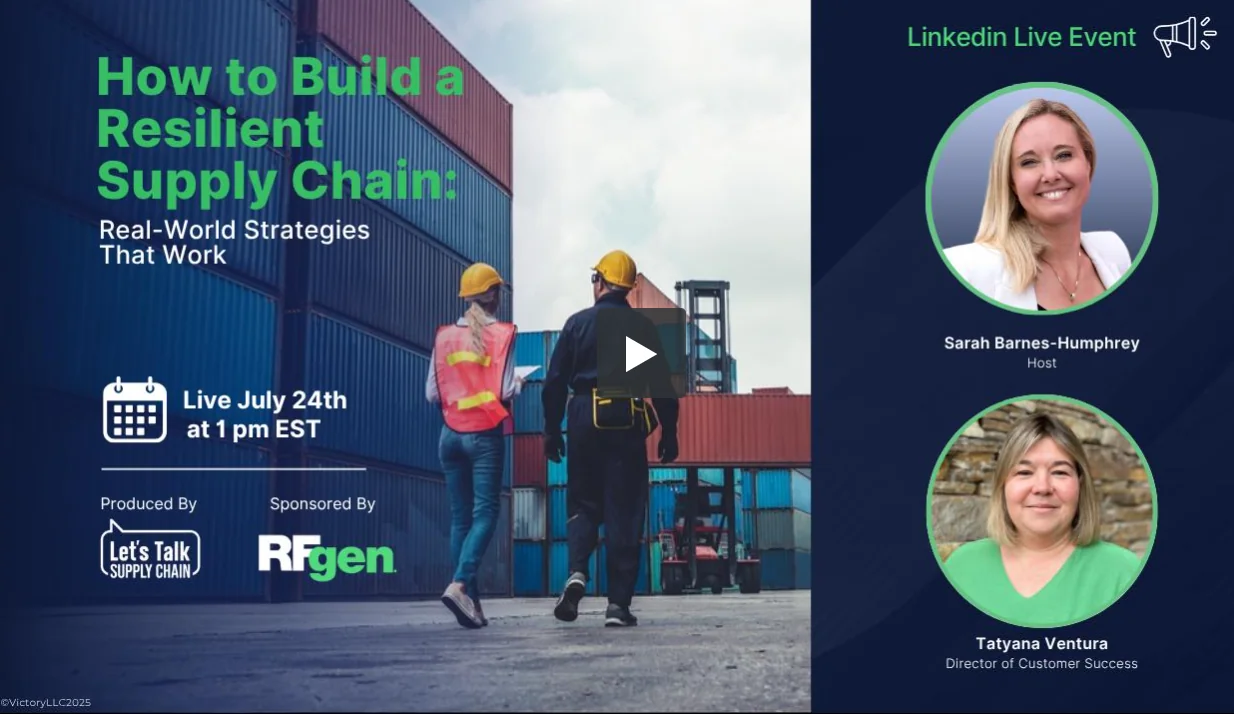

Webinar: Resilience Strategies That Build Trust in Supply Chains

Why Supply Chain AI Tech Needs Mobile Data to Take Off: Q&A with Saumya Saxena

Reimagining Mobile AIDC: AI, Hybrid Tracking & Zero-Trust Security at the Edge

Don’t Hit Pause: How Supply Chain Innovation Is Your Best Defense Against Uncertainty

Transforming ERP Adoption with User-Friendly UI Design

Learn how user-friendly UI/UX design revolutionizes ERP system adoption and why using a mobile solution offers a low-cost alternative. Learn about the challenges, strategies, and...

Read MoreFIFO Inventory Management: Fundamentals Critical for Business Success

Explore the essentials of FIFO inventory management and its strategic value for businesses. Learn how it ensures accuracy in stock rotation, cost analysis, and financial...

Read More3 Ways to Accelerate Your Inventory Management

Efficient and cost-effective inventory management is crucial to quickly changing liabilities into opportunities in your warehouse.

Read MorePackaging for the Planet: The Benefits of Sustainable & Innovative Packaging for Businesses

In recent years, many companies have become more aware of the benefits of sustainable packaging, such as, reduced shipping costs.

Read MoreState of the Industry: Past, Present and Future of Mobile Barcoding (3-Part Series)

Mobile barcoding is essential to inventory management and maintaining movement throughout supply chains, but it all began with a simple idea.

Read MoreEffective Strategies for Scaling Manufacturing Operations

Discover practical strategies to effectively scale your manufacturing operations while minimizing challenges. Read the article to enhance your growth today.

Read More10 Inventory Management Software Features for Modern Businesses

Discover essential features of inventory management software that enhance efficiency and streamline operations. Read on to optimize your inventory today!

Read MoreInvesting in Medical Inventory Software: A Step Towards a Patient-Focused Future

Learn how medical inventory software enhances patient care by ensuring accurate supply tracking, preventing critical shortages, and optimizing inventory levels for improved efficiency.

Read MoreMastering Mobile Inventory Management for Oracle SCM Cloud: The Ultimate Guide

Companies running Oracle SCM Cloud are turning to mobile inventory solutions to maximize the benefits of their ERP investment.

Read More